Apple has reduced its overall greenhouse gas emissions by more than 55 percent since 2015, the company shared today in its 2024 Environmental Progress Report. The milestone marks important progress on the journey toward Apple 2030, the company’s ambitious goal to become carbon neutral across its entire value chain by the end of this decade. The goal centers on cutting emissions by 75 percent from 2015 levels.

“The proof of Apple’s commitment to climate action is in our progress: We’ve slashed emissions by more than half, all while serving more users than ever before,” said Lisa Jackson, Apple’s vice president of Environment, Policy, and Social Initiatives. “More hard work is ahead of us, and we’re focused on harnessing the power of innovation and collaboration to maximize our impact.”

Teams across Apple and its global supply chain have contributed to Apple 2030 and the company’s environmental efforts, driving innovations in clean energy and energy efficiency, materials, carbon removal, water stewardship, zero waste, and recycling. As Apple celebrates Earth Day with its customers around the world — including through curated environment-focused collections on podcasts, books, and more — here’s a look at 10 innovations, partnerships, and activities engaging customers and advancing global climate and environmental progress.

Paving the Way for Recycled Critical Materials

Apple’s work toward making products using only recycled and renewable materials has spurred innovation in sourcing and design — while driving major reductions in the company’s carbon footprint. This includes materials critical to the clean energy transition. Last year, 56 percent of the cobalt shipped in Apple batteries came from recycled sources, more than double the year before.1 That includes the MacBook Air with M3, the first-ever Apple product to be made with 50 percent recycled material. And in another first, 24 percent of the lithium shipped in Apple batteries last year came from certified recycled sources. For both lithium and cobalt, Apple is sourcing from post-industrial scrap and post-consumer scrap from end-of-life batteries. The company has also made strides with copper, using 100 percent recycled copper in key thermal applications in iPhone 15 and the 16-inch MacBook Pro, as well as the Taptic Engine and printed circuit boards across many product lines in the last year. The progress demonstrates real potential for recycling to help meet the growing demand for critical materials in the future.

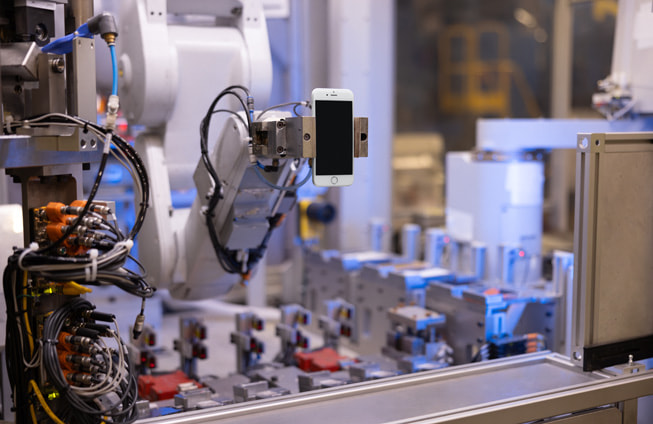

Slashing Manufacturing Emissions with Suppliers

Designing to Remove Plastic

Partnering with Communities to Drive Change

Spurring Industrywide Change with Reusable Filters

Innovating for the Future of Recycling

Building for a Greener Future

Investing in Nature with High-Quality Carbon Removal Projects

Engaging Customers and Employees in Global Recycling

Last year, nearly 12.8 million devices and accessories were sent to new owners through AppleCare and programs like Apple Trade In — more than ever before. As of today, iPhone 7 still offers Trade In value. Apple will responsibly recycle products that no longer have value, and recover the valuable materials inside so they can live a new life in future products. From reboxing old devices to send back to Apple, to organizing a collection drive, to simply passing on an old iPhone to a family member, there are so many ways customers can contribute to Apple’s environmental goals. Customers can drop off their used Apple devices at any Apple Store location, or by visiting apple.com/recycle.