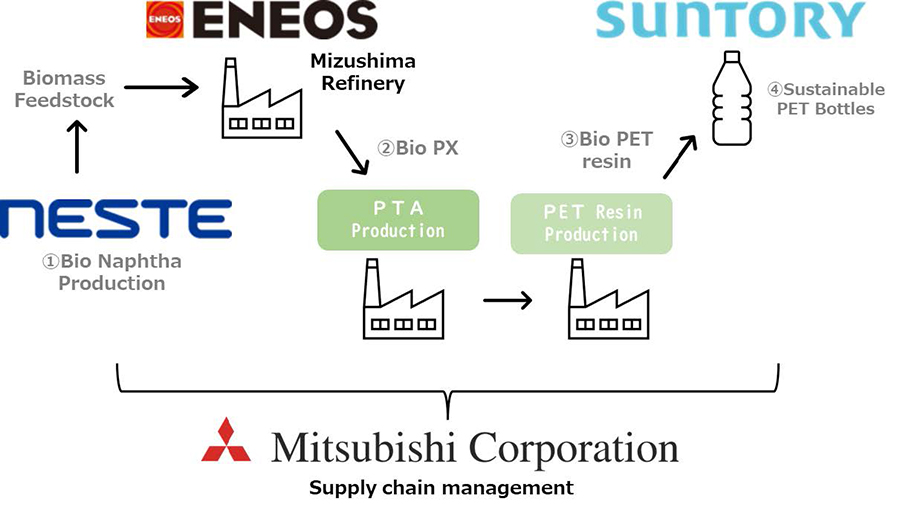

Mitsubishi Corporation, is pleased to announce that MC, Suntory Holdings Limited and ENEOS Corporation have reached an agreement to build a supply chain for sustainable PET bottles derived from biomass *1 such as used cooking oil applying a mass balance approach*2 to allocate bio-based materials .

The supply chain is as follows, and bio-based feedstock supplied by NESTE Corporation (President: Matti Lehmus, hereinafter “NESTE”) will be used as a raw material to replace fossil naphtha.

① NESTE will supply bio-based feedstock produced from to replace fossil naphtha. manufactures bio-naphtha from biomass resources such as used cooking oil. Neste uses 100% renewable raw materials such as waste and residue oils and fats, e.g. used cooking oil.

②ENEOS manufactures bio-paraxylene (PX)*3 derived from bio-naphtha at its Mizushima Refinery

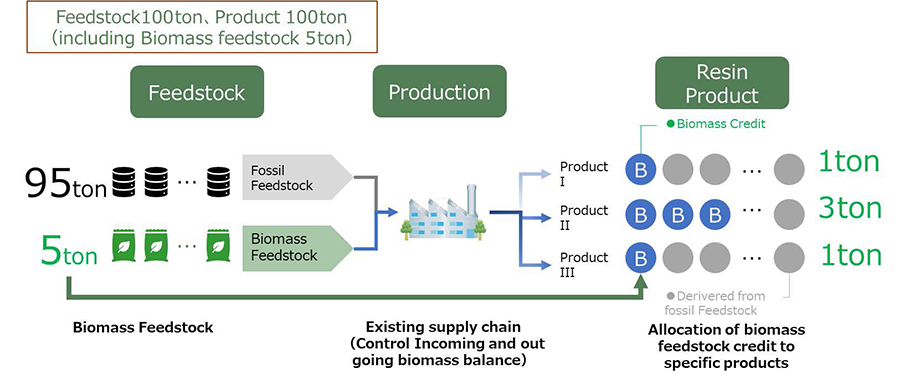

(Using the mass balance method in the production of Bio PX)

③Production of bio-high purity terephthalic acid (PTA)*4 and resin for bio-PET bottles (PET resin) using bio-PX

④ Suntory utilizes the bio-PET resin to produce sustainable PET bottles for its products

MC is responsible for the management of the entire supply chain mentioned above.

This is the world’s first*5 production of sustainable PET bottles using bio-PX derived from bio-naphtha on a commercial scale. By the end of 2023, Bio PX equivalent to approximately 35 million PET bottles will be produced, which will be used as a raw material for Suntory’s sustainable PET bottles in 2024.

*3 Paraxylene (PX) is used as a raw material for high-purity terephthalic acid (PTA), a raw material for polyester fibers and PET bottle resin conventionally manufactured from petroleum-derived naphtha.

*4 Purified terephthalic acid (PTA), a raw material for PET bottle resin, produced by oxidizing paraxylene (PX). PET bottle resin is produced by reacting PTA with ethylene glycol (MEG).

*5 As of July 31, 2023, on a commercial scale basis (according to our research).

*6 Based on a joint survey by ENEOS and Wastebox Co., Ltd. Using data from 2021 and information received from the biomass manufacturer.